New Tranny Rocks, But Fuel Problems

Got the truck back from the transmission shop. I also had them check the timing and whatnot. They said my plugs and wires were still good, but that my timing had been off. The total bill for the rebuild, shift kit, and timing was $1100 which is a lot better than I thought it would be.

I was a bit disappointed though – on the way home it was STILL doing the “stall/trying to die” thing (which I noticed it doing on the way to the shop in the first place). At first I was sort of pissed because I thought “Surely they noticed that.” But then I made a connection – it only seemed to be doing it on hills. By the time I got past the hills and on the flat stretches on the way home, it was doing ok. Then after parking on the (very inclined) driveway for a while, I started it up. Idled ok for a minute, then started to really get rough. After asking for some advice on the forums and from my buddy Dan I decided to get a new fuel pump ($40) and a new, higher flow in line fuel filter.

Boy howdy. THAT made a difference. Started right up and Brian and I took it for a spin. Did great. I thought I detected a little hesitation once or twice, but nothing major. And that could have been my imagination.

The new tranny is teh roxxors. If I come to a complete stop on a flat and then floor it, it smokes the tires. A lot. I was quite pleased.

So Tranco MIGHT turn out to be ok. But there are three things that make me hesitate to say “they have my business”.

1) I shouldn’t have had to figure out the fuel pump thing on my own. They should have caught that.

2) The tranny is COVERED in ATF. I’m going to degrease it tomorrow and see how it holds up.

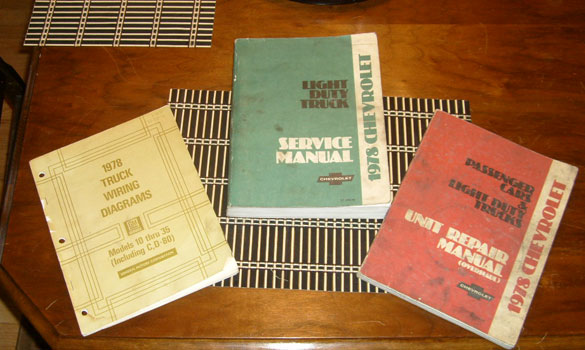

3) Ok, so I JUST finished redoing the wiring. And I had both leads going off the back of the battery towards the firewall. When I got the truck back and opened the hood for the first time I immediately noticed that the hot was going sideways, towards the driver side. Not a big deal, it had just been rotated 90 degrees. In fact I remember saying “I wonder what they had to disconnect the battery for.” Well when I took the hot off tonight to get it out of the way while I took out the fuel pump, the frikken post clamp was cracked clean in half! Now, you could tell it was just a defective part. And I didn’t even notice anything wrong until I unbolted it from the post – so probably the guy never even noticed that it cracked when it went on. But I couldn’t help but cut my eyes and wonder if he had done it and just said “his problem now.” Man I hope not – cause he see mes like a real nice guy.

Anyway. I’m outta truck money for now – gotta get caught back up after dropping all the cash on the tranny. But hey – it runs now! And well, too. So for the next little bit, it will be only labor investments – and I have one planned for tomorrow.

I am bound and determined to fix the sticky ignition.

EDIT 2014 Update:

The tranny rebuild turned out to be crap actually. I put less than 200 miles on it before it had filled the pan with brass shavings. I chucked the th350 for a street build 700r4 when I did my engine swap to get the overdrive. I still haven’t really “run” it on that new tranny, so I don’t know if that was a good move or not, but I hope it was.